AUTOMOTIVE PROFESSIONALS TRUST IN DRY ICE BLASTING

INDUSTRY LEADERS TRUST IN COLD JET

*Only available online in the United States.

DRY ICE BLASTERS FOR A NEXT LEVEL CLEAN

DRY ICE TECHNOLOGY PIONEERS

Cold Jet invented modern dry ice technology and our sole focus for 30+ years has been on developing and innovating the most technologically advanced dry ice solutions available.

Throughout our history, we have set the standard for quality, performance and reliability and we are committed to continually advancing dry ice technologies.

Cold Jet holds the original patent for modern dry ice blasting equipment – US Patent 4,617,064 (1986) – and we hold more than 250 patents worldwide.

Our dry ice blasters and pelletizers are engineered, manufactured, and/or assembled in the USA.

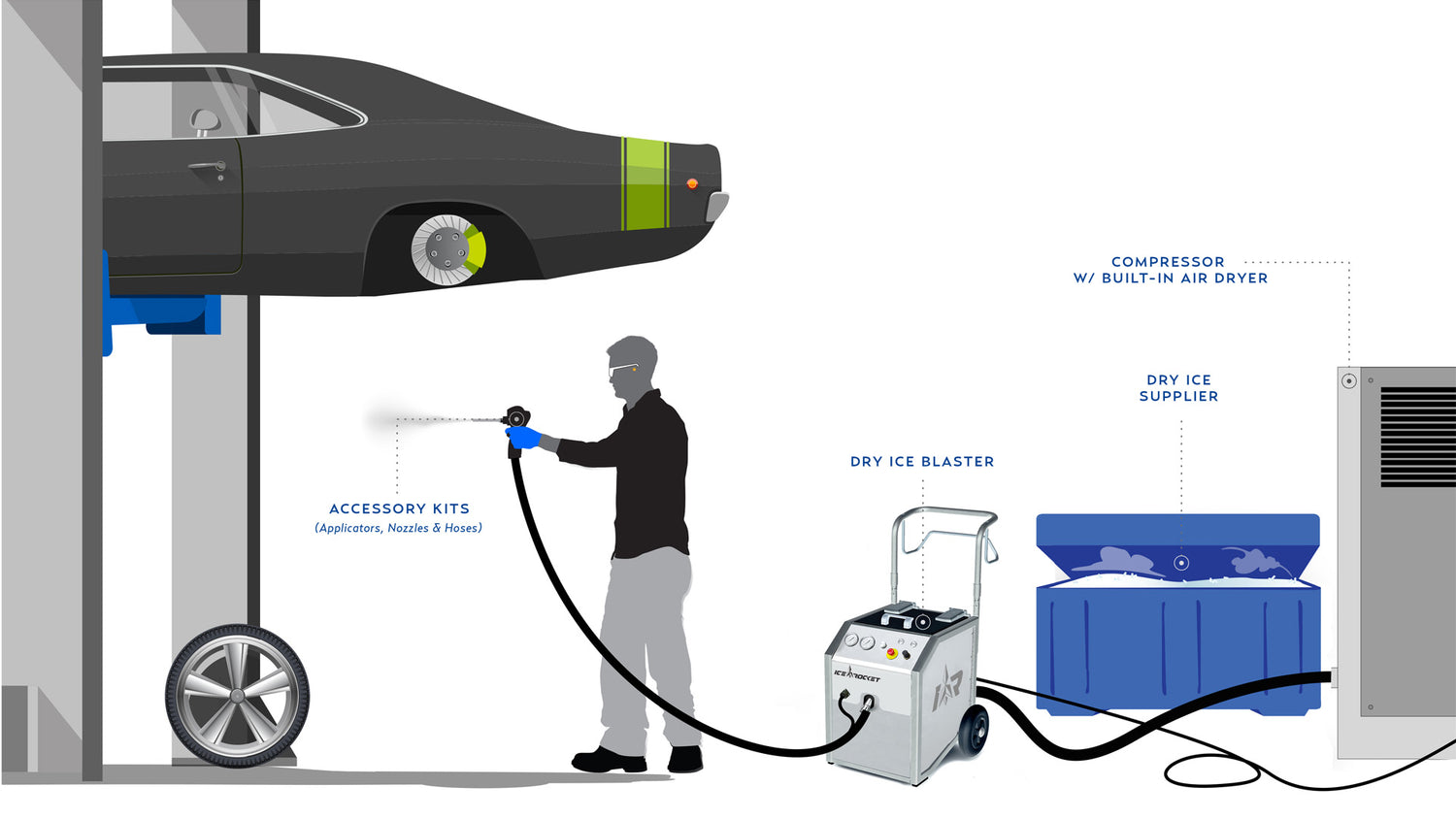

WHAT YOU NEED TO GET STARTED

There is a lot that goes into detailing a car and maintaining, or even enhancing, the value. Same goes for what is needed for a successful dry ice blasting setup. Below is the equipment we recommend to achieve superior results to blast competition out of the water...without water or harsh chemicals!

DRY ICE BLASTING REQUIREMENTS

Air Requirements

Quality air is essential for achieving optimal performance from your dry ice blaster. This is why we recommend a shop air compressor, air treatment, and a sufficiently sized air supply line.

- Air Compressor - we recommend a 15HP air compressor, minimum, with a storage tank.

- Air Treatment - dry air is a must. Dry air keeps the dry ice from clumping and clogging in the blast hose. We recommend a refrigerant dryer (sized to match HP of compressor), desiccant air dryer, water separator, or one of our after coolers.

- Air Supply line - the air supply line requirements will vary depending on which dry ice blaster you purchase from Cold Jet. Be sure to check the product specifications, but our blasters require a 3/4" or 1/2" air supply line.

Dry Ice Blaster

This goes without saying, but you will need a state-of-the-art dry ice blaster. Cold Jet is here to provide you with that! We offer a wide selection of dry ice blasters - from light detailing dry ice blasting packages to full-blown restoration packages, and everything in between.

Dry Ice Supplier

As the industry leader in dry ice technologies, Cold Jet will put you in direct contact with a local-to-you dry ice supplier no matter where you are. Cold Jet also manufacturers and sells pelletizers - machines that produce solid-state dry ice from liquid CO2 - should your consumption of dry ice justify making it in house.

Accessory Kit

Cold Jet offers many different applicators and nozzles configurations to get the job done right. Our extensive research and volume of sales into the automotive detailing industry has provided us great detail to offer an accessory configuration that works best for you. Should you want to expand your business offerings, or even explore contract cleaning, we have additional accessories for more aggression, tighter spaces, or unique applications.

Spare Parts Kit

We won't sugar coat it...our machines are mechanical. This means that things wear or break through usage. We recommend every customer has a spare parts kit on hand, that way when something does happen they can quickly fix it and get back up and running.

REGISTER FOR UPDATES

Register below for promotions and updates for the IceRocket Series!

HOW DOES DRY ICE BLASTING WORK?

FREQUENTLY ASKED QUESTIONS

ALL ABOUT DRY ICE

What is dry ice blasting?

Dry ice blasting, also called dry ice cleaning, is an environmentally sustainable cleaning and surface preparation technique. Dry ice blasting uses recycled solid carbon dioxide (CO2) pellets or MicroParticles, which are blasted at supersonic speeds and sublimate on impact, lifting dirt and contaminants off the underlying substrate. Dry ice cleaning is non-abrasive, non-conductive, non-toxic, and non-flammable. It is also chemical free, water free and does not create secondary waste streams.

How do dry ice blasters work?

Dry ice blasters blast carbon dioxide pellets or MicroParticles at supersonic speeds using compressed air. These pellets/particles then sublimate on impact and lift dirt and contaminants off the underlying substrate.

What is dry ice blasting used for?

Dry ice blasting is a non-destructive solution for cleaning, surface preparation, and parts finishing. Dry ice blasting does not require water or cleaning chemicals and does not produce secondary waste. Dry ice blasting (cleaning) can be used in industries like automotive restoration, aerospace & aviation, automotive manufacturing, contract cleaning, food & beverage, plastics & composites, historical restoration, textiles, and more.

Common applications within these industries include adhesive removal, coatings & corrosion removal, composite tool cleaning, remediation, parts finishing, and surface preparation. As you can see, dry ice blasting can be used for a wide range of applications.

What are my options for dry ice blasting equipment?

Cold Jet offers our top-of-the-line dry ice blasting equipment both new and used. As the OEM, you can be sure that you’re receiving the best equipment and the customer service/support you deserve. Click here to learn more about our buying options.

Why would I choose dry ice blasting over another detailing method?

Dry ice cleaning offers a non-toxic, environmentally sustainable alternative to traditional cleaning methods that does not create secondary waste in the cleaning process, does not require chemicals, and does not use valuable and expensive water in the cleaning process. It can also reduce time and labor costs when compared to other methods.

Is dry ice blasting dangerous?

Because dry ice blasting involves the use of dry ice, there are certain safety precautions that should be followed to ensure all personnel are safe. Some key precautions include:

- Ensuring proper ventilation

- Limiting exposure

- Identifying and labeling areas where it is possible for CO2 to accumulate

- Wearing and utilizing proper PPE such as gloves, eyewear, and tongs

Dry ice blasting is not inherently dangerous, but there are safety precautions one should always follow. To learn more about CO2 and dry ice safety, click here.

How much does dry ice cleaning cost?

Dry ice blasters range in price from $15k to $50k USD. Speak to a sales associate today for a more tailored quote.